Ways of Working115

Achieving a Sustainable and Autonomous Culture at Fenoplast

Sagar Amlani

February 10, 2020

Sagar Amlani

February 10, 2020

About Fenoplast Limited: Incorporated in 1976, Fenoplast Limited is today a leading manufacturer of PVC Leather cloth with a world-class reputation for product quality. A market leader in the OEM segment for faux leather, Fenoplast has built lasting relationships with leading international players such as TVS, Hyundai, Daimler, Volkswagen, Porsche, BMW among others. The very same expertise extends to the manufacture of rigid PVC and PVdC coated films ensuring innovative packaging solutions pharma and non-pharma applications.

Fenoplast had a vision to achieve a sustainable and autonomous culture. Prior to this however, Fenoplast had challenges with poor planning, low motivation, and loss of productivity stemming from an informal culture, employees lacking ownership, and poor co-ordination between the departments.

In 2012, a strategy was devised to create an autonomous work culture built on the principle of personal accountability, resulting in motivated employees and customer delight. This case study will explore how we achieved this.

In 2011, Sagar Amlani joined the organisation as a Vice President and given the responsibility to improve productivity and increase the bottom line. To truly understand the challenges facing the organisation, he forewent the usual induction and self-inducted himself to the team – facing a “Baptism by Fire”.

It was important to spend the first couple of weeks to understand the situation and the issues being faced by the teams. Chief among them was the communication of orders from corporate headquarters to the shop-floor. During this observation, some of the major challenges which surfaced included;

This was just at the surface. Underlying these were certain deep-rooted sentiments from the blue-collar employees. To unearth these sentiments, empathy was the best route selected.

Shutting down production for a day, Sagar called for a meeting with all the employees on the shop floor – this was a very informal heart to heart meeting.

An open forum was provided for all employees to share their feeling, issues, and grievances - without the fear of being judged as it was only the employees and Sagar present. The discussion resulted in various points which helped lay the path for correction and the journey towards improvement.

A common thread through all the challenges was the coordination between departments, management processes, and a general lack of authority. For example, there was a;

Considering the highlighted points, Sagar started gathering data for other issues pertaining to production planning, customer satisfaction, and identifying factors which impacted the bottom line.

Based on what was learnt from the data analysis and open forum, a strategy was presented to management which consisted of three phases;

Phase 1: Winning Hearts

Phase 2: Creating Autonomous Culture

Phase 3: Customer Delight

Management, after a complete study, approved the long-term strategy proposal which can be summarised thus…

“An autonomous work culture, to create symphony”

While designing a solution, it is crucial that the steps are laid out in priority order to help maintain the company’s competitive advantage. To rise to the level of professionalism of multinationals, family-owned & managed businesses require new management skills, operational competencies, and strategic intent.

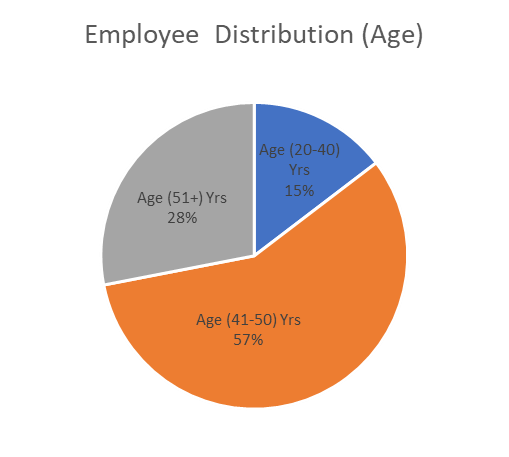

Changing the mindset of the workforce is critical to bringing any change to the organisation. For Fenoplast, to create a win-win situation new HR policies were created to address the issues highlighted in the open forum. With a diverse age distribution (with some employee working for over 3 decades) it was a very delicate situation to ensure that employee motivation and engagement was achieved. Changing organizational culture is not an easy undertaking hence the phases were designed very meticulously to ensure expected outcomes were achieved with unanimous team support.

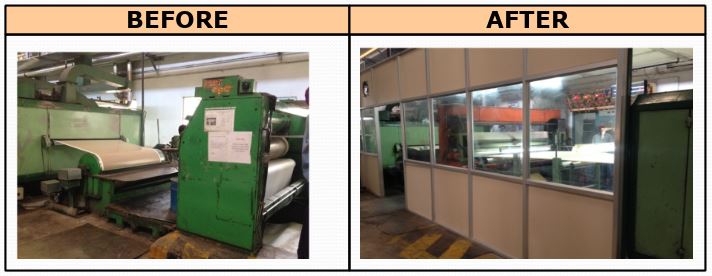

Funds were provided by the management which were utilised to build, repair, or modify the required infrastructure to support the workforce: canteen, security room, washrooms, etc. Prior to which had just been basic utilities. Flooring of the GEMBA was also taken up to reduce trolley noise, provide better workflow, and minimise material movement. Additional EOT systems were added to provide better facilities to the workers.

However, organizational culture is not stagnant. Members of an organization develop a shared belief around “what right looks like” as they interact over time and learn what yields success and what doesn’t. And when those beliefs lead to successful results, the culture evolves for the betterment of the organization. Hence our priority was to change the physical environment in order to shift workers thinking and bring in a positive transformation.

Employees responded positively and encouraged these changes, which also helped in reducing their stress. Incentives and policies were updated and displayed which, not only helped achieve team coherence, but also enhanced their confidence in the on-going transformation.

To remove any bias or favouritism, official Leave cards were printed for each employee, to be maintained by them. Motivation schemes, such as employee of the month, were implemented with selection based on;

Implementation of 5s was planned and deployed by the assigned teams and a suggestion “box” was provided for employees to share their suggestions for continual improvement. While all these phase one reformations were taking place, as part of phase two Sagar arranged training for each team and group on various tool and techniques which included QMS, 7 QC tools, 5s, RCA etc.

Implementation of 5s was planned and deployed by the assigned teams and a suggestion “box” was provided for employees to share their suggestions for continual improvement. While all these phase one reformations were taking place, as part of phase two Sagar arranged training for each team and group on various tool and techniques which included QMS, 7 QC tools, 5s, RCA etc.

These training courses were conducted over a 1-year period and process was monitored by workers on the shop-floor. This created a healthy competition among the teams and awards were given for best GEMBA (Zones) based on unbiased voting by the teams themselves.

While all this was going at a good pace, and in positive direction, there were certain people who were not pleased with the changes. Unfortunately, they caused many issues and roadblocks along the way. We started one-to-one coaching conversations with each of them until their concerns were resolved or they were moved to other units.

This intensive training helped to cultivate the right mindset and create bonds between the teams. While friendly competition added to the enthusiasm. Now that the teams were self-motivated for these small wins, it was the right time to introduce ownership.

The third phase was the most important. Each employee was asked to write down his role, authority, contribution, and any roadblocks they faced to achieve their desired outcome from the tasks. With the recent training this was not difficult for all employees to identify and share.

Considering the inputs, a system was defined to document the responsibilities, authorities, and reviewers of each process. Thus, the complete operations of the factory could now be clearly documented. With owners of each specific GEMBA areas able to bring together all the stakeholders to achieve a common outcome.

Accountability was set for each process. Owners and teams were trained to identify internal customers. And quality was given the top priority with a clear FTR (first time right) policy for production.

With all these changes, efficiency increased to a level were production output soared by 34% using the same infrastructure, quality of the output improved from 84% to 91% were each % increase added INR 1,00,000/- in the bottom line.

Overall, all three phases were competed within 2 years. The new system gave the employees the required autonomy to take certain decisions to improve productivity on the running production line which saw immediate results. And even when some of these decisions backfired, Sagar continued to support the team and the approach. Finally, regular reviews ensured that the balance of autonomy in the system was maintained. This behavioural change instilled positivity in the employees and led them to deliver even higher results.

The journey has just started for Sagar and his team…

By the time all three phases were complete, Fenoplast had achieved;

Overall, these results have been promising. We are now looking to the future for further expansion and forward integration of the changes.

Please subscribe and become a member to access the entire Business Agility Library without restriction.